Graphite is on the cusp of explosive market growth powered by a revolutionary shift to clean energy and battery-powered technologies.

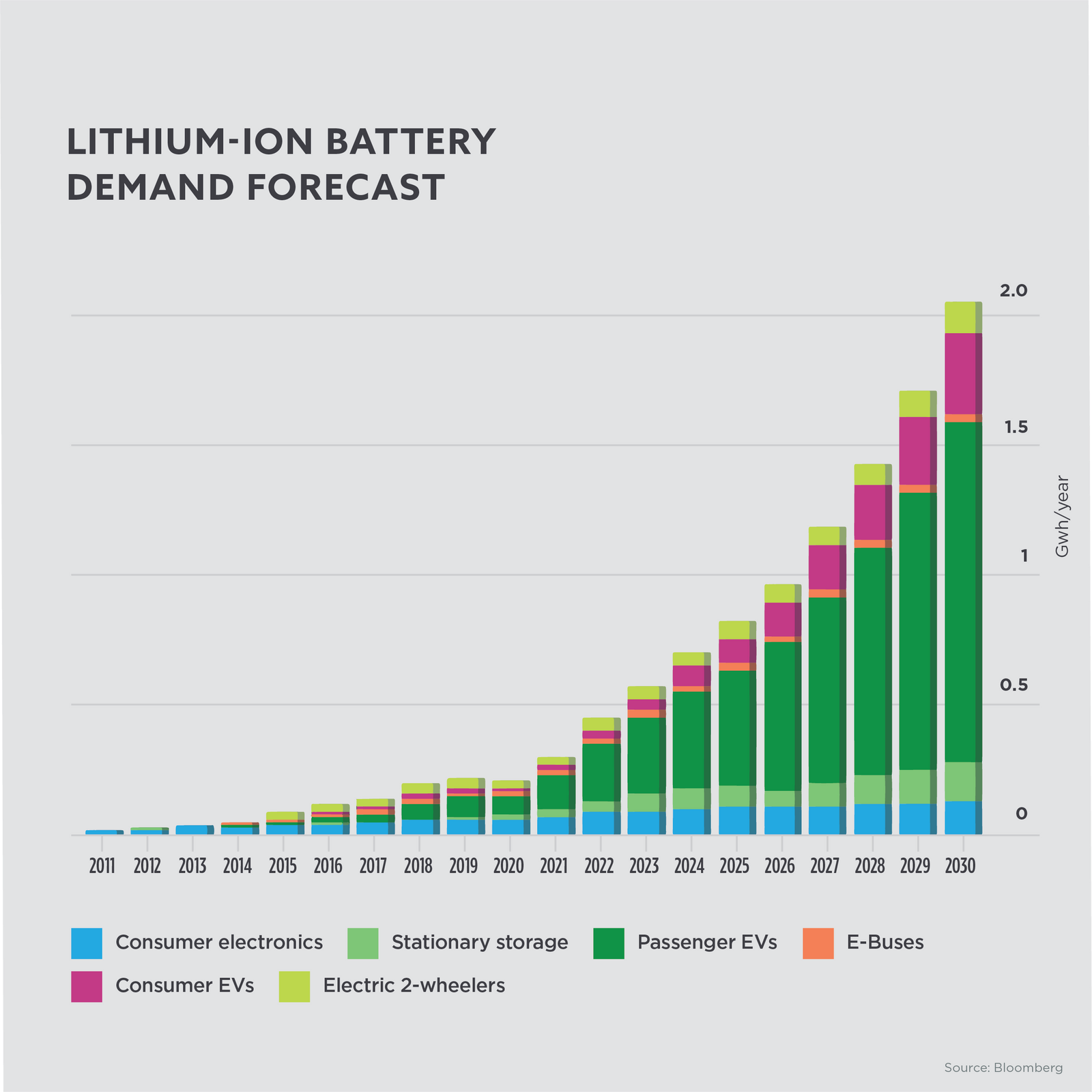

As the world strives to achieve net zero emissions by 2050, batteries are transforming the fuel-hungry transport and power sectors. The rapid uptake of electric vehicles and renewable energy is creating exponential growth in the demand for lithium-ion batteries and the commodities needed to make them.

Industry analysts expect demand for graphite from the battery sector will grow by a massive 1,400% between 2020 and 2050 (Wood McKenzie, 2021), while a graphite shortage is looming with an expected deficit of 20,000 tonnes in 2022 (Benchmark Minerals Intelligence). To put it into a global perspective, the deficit means 250,000 EV batteries will not be produced — less than the Chinese EV market alone is expected to need. A World Bank Report expects the graphite industry to grow at a compound annual growth rate (CAGR) of 5.3% to reach US$21.6 billion by 2027.

International Graphite is evolving as an important new global supplier of graphite products, including battery anode material. It will offer global manufacturers a reliable, high quality source of processed graphite made in Australia – a location they know and trust.

Demand for graphite is accelerating

Electric vehicles are driving worldwide demand for batteries and battery anode graphite. EV sales topped a record 10 million in 2022 – tripling in just four years – and well ahead of forecasts. The demand for electric cars is expected to continue to boom with the number of electric cars on the world’s roads jumping to more than 26 million in 2022. There are now more EVs sold in a week than in the whole of 2012, according to the International Energy Agency.

Soaring need for batteries

30% year-on-year growth worldwide led by Li-ion batteries in EVs: McKinsey

Globally, decarbonisation is revolutionising the transport and energy markets, creating unprecedented demand for batteries, particularly lithium-ion batteries for electric vehicles, from ebikes, cars and buses to planes and ships. Processed graphite makes up 95% of the battery anode (negative electrode) and is forecast to be in short supply for the next two decades as the electric vehicle revolution ramps up.

Global graphite shortage

Existing operational supply and potential supply cannot meet implied demand: Benchmark Minerals Intelligence

Currently, the world is bracing for a graphite shortage as growing demand outstrips the expected supply from all known projects. The US and Australia have no manufacturing plants that can supply automotive-grade graphite at scale and China controls 84% of global supply. Europe is leading the world in decarbonisation and experiencing explosive growth in its battery industry. From 2035 all new vehicles will be required to have zero emissions so it too is searching for additional graphite supply.